-

Standard: CE CertificationNumber: ET1003101005Issue Date: 2019-03-10Expiry Date: 2024-10-22

-

Standard: EMS CertificationNumber: 06415E10529ROMIssue Date: 2019-07-28Expiry Date: 2022-07-27

-

Standard: CQCNumber: 00115Q20697R2M/3401Issue Date: 2019-06-20Expiry Date: 2022-06-15

-

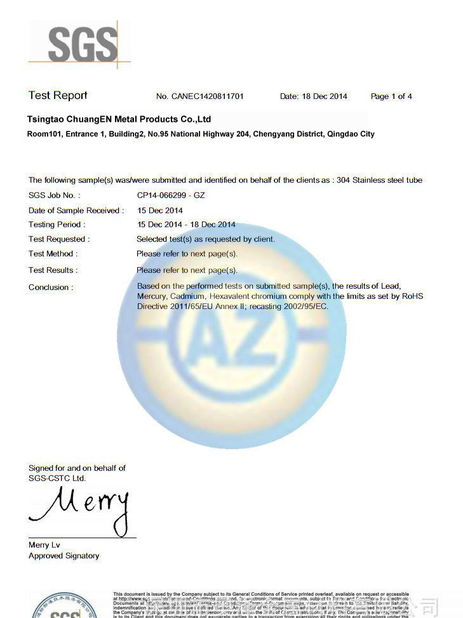

Standard: SGSNumber: CANEC1420811701Issue Date: 2014-12-18Expiry Date:

Quality control is essential to building a successful business that delivers products that meet or exceed customers' expectations. It also forms the basis of an efficient business that minimizes waste and operates at high levels of productivity.

Quality is critical to satisfying your customers and retaining their loyalty so they continue to buy from you in the future. Quality products make an important contribution to long-term revenue and profitability. They also enable you to charge and maintain higher prices. ... Most of us needs quality products and services.

There are seven primary quality control tools which include:

Metallurgical, hardness, hardenability, tension, ductility, compression, fatigue, impact, wear, corrosion, creep, machinability, radiography, magnetic particle, ultrasonic, and eddy current are some of the major tests that are performed by quality control personnel.

Checklists. At its most basic, quality control requires you to check off a list of items that are imperative to manufacture and sell your product.

Fishbone diagram. ...

Control chart. ...

Stratification. ...

Pareto chart. ...

Histogram. ...

Scatter Diagram.

Remove the oxide layer on the steel, put a drop of water, rub with copper sulfate, after rubbing, such as not discolored, generally stainless steel; such as purplish red, non-magnetic for high manganese steel, magnetic generally ordinary steel or low alloy steel.