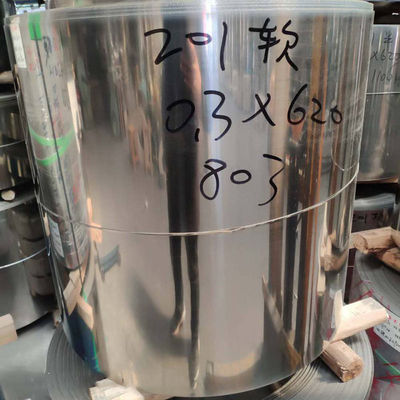

ASTM A240 Mirror Finish Cold Rolled Stainless Steel Coil 201 SS

Product Details:

| Place of Origin: | China |

| Brand Name: | TISCO,BAOSTEEL,POSCO,JISCO,LISCO |

| Certification: | MTC; SGS |

| Model Number: | 201 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Ton |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Coils covered with waterproof protective packing materails |

| Delivery Time: | 3-15 working days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 200 tons per month |

|

Detail Information |

|||

| Name: | ASTM 201 | Width: | 1219 Mm |

|---|---|---|---|

| Technique: | Cold Rolled | Price Term: | FOB, CFR, CIF |

| Standard: | 201 | Thickness: | 0.3-3 Mm |

| Surface: | 8K Finish | Packing: | Standard Seaworthy Package |

| Statement: | In Stock | ||

| Highlight: | ASTM Cold Rolled Stainless Steel Coil,Cold Rolled Stainless Steel Coil 201,ASTM CR steel coil |

||

Product Description

ASTM A240 Mirror Finish Cold Rolled Stainless Steel Coil 201 SS

201 stainless steel circulating on the market, nickel content is about 1 nickel, according to the requirements of

the composition of large differences. This type of steel is mainly used to replace 304 stainless steel in some specific

applications. 201 steel contains manganese and will rust in humid and salty air for a long time. Because of the

relationship between manganese element color will be darker than 304 steel, but the naked eye is more difficult

to distinguish. Due to the different nickel content, 201 stainless steel is less resistant to corrosion than 304. The

higher carbon content makes 201 stainless steel harder and more brittle than 304.

Product introduction :

| Commodity | ASTM A240 Mirror Finish Cold Rolled Stainless Steel Coil 201 SS |

| Grade | 201 |

| Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

| Certification | SGS,BV,IQI,TUV,ISO,etc |

| Thickness | 0.3-3 mm |

| Width |

1219 mm |

| Length | as per customers'requirements |

| Surface | Mirror Finish |

| Standard | JIS,AISI,ASTM,GB,DIN, BS EN, AS |

| Delivery time | About 15 days or based on the sales contract |

| MOQ | 1 Ton |

| Advantages |

Showing the splendor of your quality, wearresistant as well , |

Chemical composition:

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo | N |

| 201 | ≤0.15 | ≤1.00 | 5.5~7.5 | ≤0.060 | ≤0.03 | 0.80-1.0 | 16.00-18.00 | - | ≤0.2 |

Mechanical property:

| Grade | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) | HBW | HRB | HV | Density |

| 201 | ≥520 | ≥275 | ≥55 | ≤241 | ≤100 | ≤253 | 7.93g/cm³ |

Gauge Size Table:

| Gauge | SS inch | SS mm | Mild Steel | Galvanized Steel |

| 3 | 0.25 | 6.35 | 0.2391 | |

| 4 | 0.2344 | 5.95376 | 0.2242 | |

| 5 | 0.2187 | 5.55498 | 0.2092 | |

| 6 | 0.2031 | 5.15874 | 0.1943 | |

| 7 | 0.1875 | 4.7625 | 0.1793 | |

| 8 | 0.165 | 4.191 | 0.1644 | 0.168 |

| 9 | 0.1562 | 3.96748 | 0.1495 | 0.1532 |

| 10 | 0.1406 | 3.57124 | 0.1345 | 0.1382 |

| 11 | 0.125 | 3.175 | 0.1196 | 0.1233 |

| 12 | 0.1094 | 2.77876 | 0.1046 | 0.1084 |

| 13 | 0.0937 | 2.37998 | 0.0897 | 0.0934 |

| 14 | 0.0781 | 1.98374 | 0.0747 | 0.0785 |

| 15 | 0.0703 | 1.78562 | 0.0673 | 0.071 |

| 16 | 0.0625 | 1.5875 | 0.0598 | 0.0635 |

| 17 | 0.0562 | 1.42748 | 0.0538 | 0.0575 |

| 18 | 0.05 | 1.27 | 0.0478 | 0.0516 |

| 19 | 0.0437 | 1.10998 | 0.0418 | 0.0456 |

| 20 | 0.0375 | 0.9525 | 0.0359 | 0.0396 |

| 21 | 0.0344 | 0.87376 | 0.0329 | 0.0366 |

| 22 | 0.0312 | 0.79248 | 0.0299 | 0.0336 |

Surface finish :

![]()

Surface:

![]()

| Surface Finish | Definition | Application |

| 2B | Finished by heat treatment, pickling after cold rolling. Followed by skin pass line to be more brighter and smooth surface | General application Medical instruments, Tableware |

| BA | Bright heat treament after cold rolling | Kitchen utensil, kitchenware, architectural |

| 8K | A mirror-like reflective surface by polishing with finer abrasives over 800mesh | Construction, mirrors, plate sets, decoration elevators |

| HL | Finished by continuous linear polishing | Architectural purpose, Escalators, kitchenware, vehicles |

| NO.1 | Finished by hot rolling, annealing and picking, characterized by white pickled surface | Chemical industry Equipment, industrail tanks |

| NO.4 | Polishing with NO.150 to NO.180 mesh abrasives specified in JISR6001 | Kitchen utensils, Building Construction, Medical equipment |

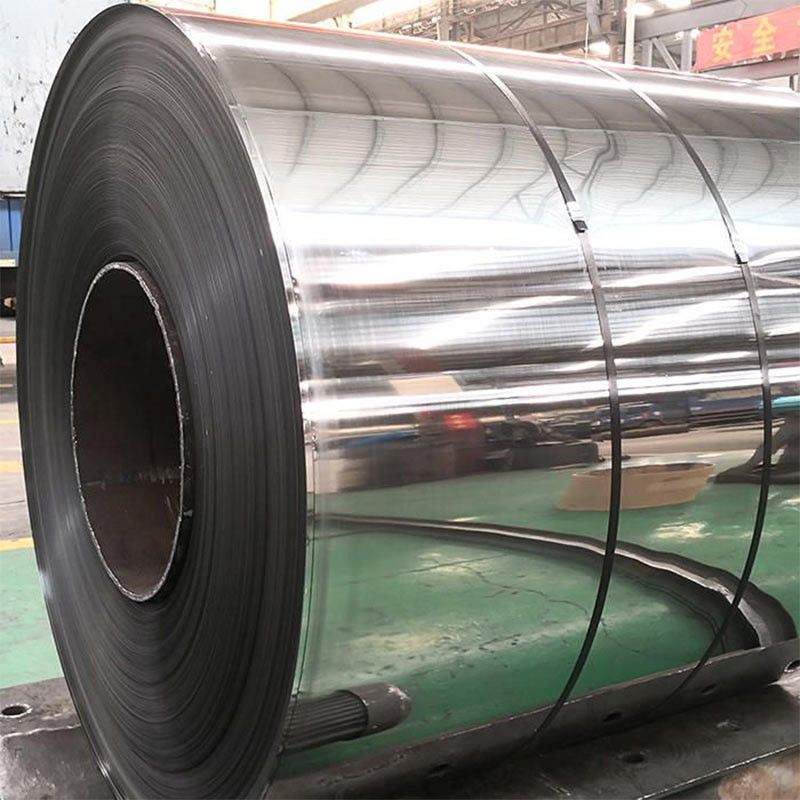

Cold Rolled Process:

Cold rolling: hot rolled steel coil is used as raw material for cold continuous rolling after acid pickling to remove oxide scale. The finished product is hard rolled coil. Due to the cold work hardening caused by continuous cold deformation, the strength and hardness of hard rolled coil increase and the toughness and plasticity index decrease. Therefore, the stamping performance will deteriorate and can only be used for simple deformed parts. The hard rolled coil can be used as the raw material of the hot-dip galvanizing plant, because the hot-dip galvanizing units are equipped with annealing lines. The weight of rolled hard coil is generally 6 ~ 13.5 tons. The hot-rolled pickling coil is continuously rolled at room temperature. The inner diameter is 610mm.

![]()

Packaging :

![]()

Product Display:

![]()

![]()