No 1 Finish Hot Rolled Stainless Steel Coil 500-1500mm Width Tp321 Astm 240

Product Details:

| Place of Origin: | China |

| Brand Name: | TISCO,BAOSTEEL,POSCO,JISCO,LISCO |

| Certification: | MTC; SGS |

| Model Number: | 321 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Ton |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Coils covered with waterproof protective packing materails |

| Delivery Time: | 10-15 working days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 tons per month |

|

Detail Information |

|||

| Name: | Hot Rolled 321 Stainless Steel Coil | Width: | 600mm,1000mm,1219mm,1500mm |

|---|---|---|---|

| Technique: | Hot Rolled | Type: | 321 |

| Thickness: | 3-6mm | Color: | As Customer's Requirments |

| Material: | 300 Series | Application: | Industrial, Decorative |

| Tolerance: | ±5% | Item: | SGS, MTC, ASTM Standard |

| Highlight: | no 1 hot rolled stainless steel coil,tp321 hot rolled stainless steel coil,astm240 stainless steel hot rolled coil |

||

Product Description

No.1 Finish Hot Rolled Stainless Steel Coil 500-1500mm Width TP321 ASTM 240

Type 321 is a stabilized stainless steel which offers as its main advantage an excellent resistance to intergranular corrosion following exposure to temperatures in the chromium carbide precipitation range from 800 to 1500° F (427 to 816° C). Type 321 is stabilized against chromium carbide formation by the addition of titanium.

Product introduction :

| Commodity | No.1 Finish Hot Rolled Stainless Steel Coil 500-1500mm Width TP321 ASTM 240 |

| Grade | 321 |

| Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

| Certification | SGS,BV,IQI,TUV,ISO,etc |

| Thickness | mm |

| Width |

500-1500 mm |

| Length | as per customers'requirements |

| Surface | 2B BA Fiknish |

| Standard | JIS,AISI,ASTM,GB,DIN |

| Delivery time | About 15days or based on the sales contract |

| MOQ | 1 Ton |

| Advantages |

better ductility and resistance to stress fracture |

Mechanical property:

| 321 | Ys (Mpa) | Ts (Mpa) | El (%) | HV |

| Standard | ≥205 | ≥520 | ≥40 | ≤200 |

| General | 310 | 620 | 53 | 155 |

Chemical Position:

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 | ≤1.00 | 5.5~7.5 | ≤0.060 | ≤0.03 | 3.5~5.5 | 16.00~18.00 | - |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.0 | ≤0.060 | ≤0.03 | 4.0~6.0 | 17.00~19.00 | - |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 6.00~8.00 | 16.00~18.00 | - |

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.00~10.00 | 17.00~19.00 | - |

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.00~10.00 | 18.00~20.00 | - |

| 304L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 9.00~13.00 | 18.00~20.00 | - |

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 19.00~22.00 | 24.00~26.00 | - |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 12.00~15.00 | 16.00~18.00 | 2.00~3.00 |

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 9.00~13.00 | 17.00~19.00 | - |

| 410 | ≤0.15 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.03 | 11.500~13.50 | - | |

| 430 | ≤0.12 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | - |

![]()

Surface finish :

![]()

| Surface Finish | Definition | Application |

| 2B | Finished by heat treatment, pickling after cold rolling. Followed by skin pass line to be more brighter and smooth surface | General application Medical instruments, Tableware |

| BA | Bright heat treament after cold rolling | Kitchen utensil, kitchenware, architectural |

| 8K | A mirror-like reflective surface by polishing with finer abrasives over 800mesh | Construction, mirrors, plate sets, decoration elevators |

| HL | Finished by continuous linear polishing | Architectural purpose, Escalators, kitchenware, vehicles |

| NO.1 | Finished by hot rolling, annealing and picking, characterized by white pickled surface | Chemical industry Equipment, industrail tanks |

| NO.4 | Polishing with NO.150 to NO.180 mesh abrasives specified in JISR6001 | Kitchen utensils, Building Construction, Medical equipment |

Service :

We had our own factory to do slitting re-rolling and finish treatment machine,PVC and interleaving paper we will using with our machine for you,could protect stainless steel surface from damage or any scratches,

1. CNC Flame Cutting Machine

2. CNC Plasma Cutting Machine

3. CNC Laser Cutting Machine

4. Bending Machine

5. Shearing Machine

6. Punch Machine

7. Driving Machine

Brand Cross Reference Table:

| GB NEW BRAND | JIS | ASTM | UNS | KS | BS EN | AS |

| 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 201-2 |

| 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - |

| 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 301 |

| 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 304 |

| 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 304L |

| 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | 304N1 |

| 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | 304N2 |

| 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | - | 304LN |

| 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | 305 |

| 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | 309S |

| 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | 310S |

| 06Cr17Ni12Mo2 | SUS316 | 3016 | S31600 | STS316 | 1.4401 | 316 |

| 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | - | 1.4571 | 316Ti |

| 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 316L |

| 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | - | 316N |

| 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | 316LN |

| 06Cr18Ni12Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | 316J1 |

| 022Cr18Ni14Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - |

| 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | - | 317 |

| 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | 317L |

| 06Cr18Ni11Tji | SUS321 | 321 | S32100 | STS321 | 1.4541 | 321 |

| 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.455 | 347 |

| 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 410 |

| 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 420 |

| 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 430 |

![]()

Packaging :

![]()

No.1 Finish Hot Rolled Stainless Steel Coil 500-1500mm Width TP321 ASTM 240 Packaging Details :

1: Coils covered with waterproof protective packing materails ;

2: Then loaded in strong metal pallets +angle bar protection +steel strip ;

3: Well loaded and be transported to the loading port .

The innner size container as below :

1: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM ;

2: 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM ;

3: 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM.

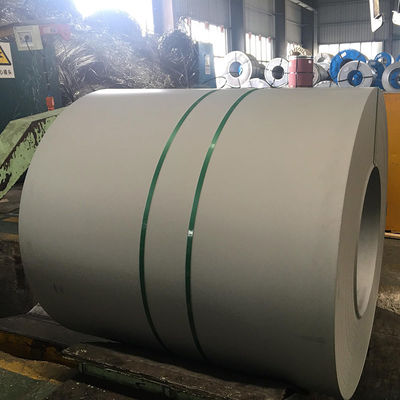

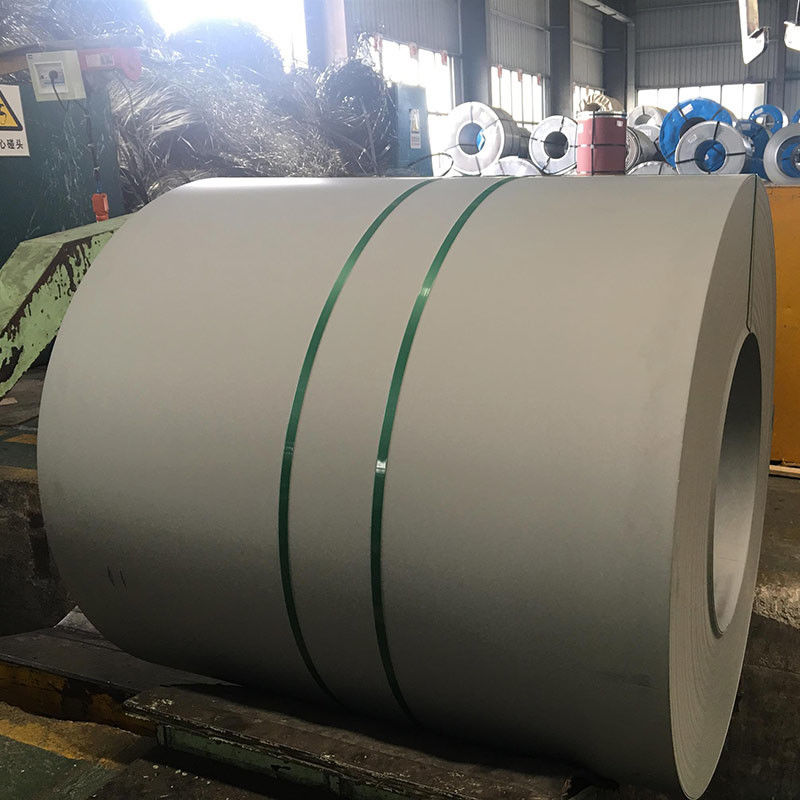

Product Display:

![]()

![]()

![]()

WHY CHOOSE US:

Q1: What is your terms of payment?

A: 30% T/T in advance, the balance 70% before delivery. We will show you the photos of products and package before you pay the balance.

Q2: what is the terms of delivery?

A: FOB, CIF, CFR,

Q3: What is the terms of packing?

A: generally, we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers' requirement.

Q4: What is your delivery time?

A: For stocks, we could transport the goods to loading port within 7 days after we received your deposit.

For production period, it usually takes about 15 days-30 days after receiving the deposit.

Q5: Could you produce according to the samples?

A : Yes, we could customer-made by your samples or technique drawings, we could build the mold and fixtures.

Q6: Could you provide the samples?

A: yes, we could provide the free samples on conditons it is available in stocks, however, the the transportation fee is borne by buyer.