Dx52D SECC Corrugated Roof Sheet Hot Dip 0.5mm CGI SGCC

Product Details:

| Place of Origin: | China |

| Brand Name: | TISCO,BAOSTEEL,POSCO,JISCO,LISCO |

| Certification: | MTC; SGS |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Ton |

|---|---|

| Price: | Negotiable |

| Packaging Details: | waterproof paper and steel strip reinforcement,one package about 2 tons,Load in 20' or 40' GP |

| Delivery Time: | 7-15 working days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 tons per month |

|

Detail Information |

|||

| Name: | Corrugated Roof Sheet 0.5mm | Standard: | JIS G3302 1998, ASTM A653M/A924M 2004 |

|---|---|---|---|

| Thickness: | 0.12-6.0 Mm | Coating: | Double Side |

| Width: | 100-1500mm Or As Required | Length: | 1000mm-12000mm Or As Your Request |

| Spangle: | No Spangle | Delivery Time: | 7-15 Days |

| Tolerance: | Thickness& Width:+/-0.02mm | Application: | Building |

| Highlight: | SECC Corrugated Roof Sheet,0.5mm Corrugated Roof Sheet,CGI Hot Dip Corrugated Roof Sheet |

||

Product Description

What is spangle

The dictionary defines “spangle” as a glittering object. When the word spangle is used to describe the surface appearance of galvanized steel sheet, it means the typical snowflake-like or six-fold star pattern that is visible to the unaided eye.

feature of galvanized sheet. Spangle size can be affected not only by the zinc chemistry and cooling rate, but also by other factors such as the smoothness of the substrate. Consistently controlling spangle formation to a specified size, and then verifying compliance, would be an extremely difficult task. For this reason, spangle size terminology is qualitative. It is defined in ASTM A653/A653M, Specification for Steel Sheet, Zinc-Coated (Galvanized) as follows:

Product introduction:

| Product Name |

Dx52D SECC Galvanized Corrugated Roof Sheet 0.5mm CGI SGCC SPEC

|

|

| Standard | JIS G3302 1998, ASTM A653M/A924M 2004, all according to the customer's request | |

| Grade | DX51D,DX52D,DX53D,SGCC,SPGC,SECC,S220GD,S280GD,DC01,DC02,DC03 etc. | |

| SIZE | Thickness | 0.12-6.0 mm or as required |

| Width | 100-1500mm or as required | |

| Length | 1000mm-12000mm or as your request | |

| Tolerance | Thickness& Width:+/-0.02mm | |

| Technique | Hot Rolled/cold rolled | |

| Coating Weight | 30-275g/m2,double side | |

| Spangle | Big spangle, normal spangle, small spangle, non-spangle | |

| Delivery Time | within 7-15 days after receive 30% deposit or depend on Quantity | |

| Application | Building , Corrugated sheet Roofing, electrical, Appliances, Automobile industry,Transport Packaging ,Machinery processing ,Interior decoration , Medical | |

| Packing | Seaworthy packaging: PVC+waterproof paper, seaworthy wooden packaging or as required | |

Gauge and Thickness Inch:

| Gauge | Mild Steel | Aluminum | Galvanized Steel | Stainless Steel |

| 3 | 0.2391 | 0.2294 | 0.2500 | |

| 4 | 0.2242 | 0.2043 | 0.2344 | |

| 5 | 0.2092 | 0.1819 | 0.2187 | |

| 6 | 0.1943 | 0.1620 | 0.2031 | |

| 7 | 0.1793 | 0.1443 | 0.1875 | |

| 8 | 0.1644 | 0.1285 | 0.1680 | 0.1650 |

| 9 | 0.1495 | 0.1144 | 0.1532 | 0.1562 |

| 10 | 0.1345 | 0.1019 | 0.1382 | 0.1406 |

| 11 | 0.1196 | 0.0907 | 0.1233 | 0.1250 |

| 12 | 0.1046 | 0.0808 | 0.1084 | 0.1094 |

| 13 | 0.0897 | 0.0720 | 0.0934 | 0.0937 |

| 14 | 0.0747 | 0.0641 | 0.0785 | 0.0781 |

| 15 | 0.0673 | 0.0571 | 0.0710 | 0.0703 |

| 16 | 0.0598 | 0.0508 | 0.0635 | 0.0625 |

| 17 | 0.0538 | 0.0453 | 0.0575 | 0.0562 |

| 18 | 0.0478 | 0.0403 | 0.0516 | 0.0500 |

| 19 | 0.0418 | 0.0359 | 0.0456 | 0.0437 |

| 20 | 0.0359 | 0.0320 | 0.0396 | 0.0375 |

| 21 | 0.0329 | 0.0285 | 0.0366 | 0.0344 |

| 22 | 0.0299 | 0.0253 | 0.0336 | 0.0312 |

| 23 | 0.0269 | 0.0226 | 0.0306 | 0.0281 |

| 24 | 0.0239 | 0.0201 | 0.0276 | 0.0250 |

| 25 | 0.0209 | 0.0179 | 0.0247 | 0.0219 |

| 26 | 0.0179 | 0.0159 | 0.0217 | 0.0187 |

| 27 | 0.0164 | 0.0142 | 0.0202 | 0.0172 |

| 28 | 0.0149 | 0.0126 | 0.0187 | 0.0156 |

| 29 | 0.0135 | 0.0113 | 0.0172 | 0.0141 |

| 30 | 0.0120 | 0.0100 | 0.0157 | 0.0125 |

| 31 | 0.0105 | 0.0089 | 0.0142 | 0.0109 |

| 32 | 0.0097 | 0.0080 | 0.0134 | 0.0102 |

| 33 | 0.0090 | 0.0071 | 0.0094 | |

| 34 | 0.0082 | 0.0063 | 0.0086 | |

| 35 | 0.0075 | 0.0056 | 0.0078 | |

| 36 | 0.0067 | 0.0070 |

Chemical Composition:

| Category | Grade | Chemical Composition,%,≤ | ||||||

| hot dip galvanized | For cold forming National sign | C | Si | Mn | P | S | Ti | |

| DX51D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | ||

| DX52D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | ||

| DX53D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | ||

| DX54D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | ||

| DX56D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | ||

| DX57D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | ||

| For cold forming US grade | CSA | 0.1 | 0.6 | 0.03 | 0.035 | 0.025 | ||

| CSB | 0.02-0.15 | 0.6 | 0.03 | 0.035 | 0.025 | |||

| CSC | 0.08 | 0.6 | 0.1 | 0.035 | 0.025 | |||

| FSA | 0.1 | 0.5 | 0.02 | 0.035 | 0.025 | |||

| FSB | 0.02-0.08 | 0.5 | 0.02 | 0.03 | 0.025 | |||

| DDS A | 0.06 | 0.5 | 0.02 | 0.025 | 0.025 | |||

| DDS B | 0.02 | 0.5 | 0.1 | 0.025 | 0.15 | |||

| EDDS | 0.02 | 0.4 | 0.02 | 0.02 | 0.15 | |||

| For cold forming Japanese grade | SGCC | 0.15 | 0.8 | 0.05 | 0.03 | |||

| SGCD1 | 0.12 | 0.6 | 0.04 | 0.03 | ||||

| SGCD2 | 0.1 | 0.45 | 0.03 | 0.03 | ||||

| SGCD3 | 0.08 | 0.45 | 0.03 | 0.03 | ||||

| SGCD4 | 0.06 | 0.45 | 0.03 | 0.03 | ||||

| For structure Japanese grade | SGC340 | 0.25 | 1.7 | 0.2 | 0.035 | |||

| SGC400 | 0.25 | 1.7 | 0.2 | 0.035 | ||||

| SGC440 | 0.25 | 2 | 0.2 | 0.035 | ||||

| SGC490 | 0.3 | 2 | 0.2 | 0.035 | ||||

| SGC510 | 0.3 | 2.5 | 0.2 | 0.035 | ||||

| For structure National sign | S220GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | ||

| S250GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | |||

| S280GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | |||

| S320GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | |||

| S350GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | |||

| S550GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | |||

| hot dip Galvalume | For cold formingNational sign | DX51D+AZ | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 |

| DX52D+AZ | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | ||

| DX53D+AZ | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | ||

| DX54D+AZ | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | ||

| For structureNational sign | S220GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | ||

| S250GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | |||

| S280GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | |||

| S320GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | |||

| S350GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | |||

| S550GD+Z | 0.02 | 0.6 | 0.7 | 0.1 | 0.045 | |||

Physical Property:

| Category | Grade | Yield Strength | Tensile strength | Elongation | |

| hot dip galvanized | For cold formingNational sign | ReL/Mpa | RM/Mpa | A80mm/% | |

| DX51D+Z | 270-500 | ≥22 | |||

| DX52D+Z | 140-300 | 270-420 | ≥26 | ||

| DX53D+Z | 140-260 | 270-380 | ≥30 | ||

| DX54D+Z | 120-220 | 260-350 | ≥36 | ||

| DX56D+Z | 120-280 | 260-350 | ≥39 | ||

| DX57D+Z | 120-170 | 260-350 | ≥41 | ||

| For cold formingUS grade | CSA | 170-380 | ≥20 | ||

| CSB | 250-380 | ≥20 | |||

| CSC | 170-410 | ≥15 | |||

| FSA | 170-310 | ≥26 | |||

| FSB | 170-310 | ≥26 | |||

| DDS A | 140-240 | ≥32 | |||

| DDS B | 170-280 | ≥32 | |||

| EDDS | 105-170 | ≥40 | |||

| For cold formingJapanese grade | SGCC | ≥205 | ≥270 | ||

| SGCD1 | ≥270 | ≥36 | |||

| SGCD2 | ≥270 | ≥38 | |||

| SGCD3 | ≥270 | ≥40 | |||

| SGCD4 | ≥270 | ≥42 | |||

| For structureJapanese grade | SGC340 | ≥245 | ≥340 | ≥20 | |

| SGC400 | ≥295 | ≥400 | ≥18 | ||

| SGC440 | ≥335 | ≥440 | ≥18 | ||

| SGC490 | ≥365 | ≥490 | ≥16 | ||

| SGC510 | ≥560 | ≥570 | |||

| For structureNational sign | S220GD+Z | ≥220 | ≥300 | ≥20 | |

| S250GD+Z | ≥250 | ≥330 | ≥19 | ||

| S280GD+Z | ≥280 | ≥360 | ≥18 | ||

| S320GD+Z | ≥320 | ≥390 | ≥17 | ||

| S350GD+Z | ≥350 | ≥420 | ≥16 | ||

| S550GD+Z | ≥550 | ≥560 | |||

| hot dip Galvalume | For cold formingNational sign | DX51D+AZ | 270-500 | ≥22 | |

| DX52D+AZ | 140-300 | 270-420 | ≥26 | ||

| DX53D+AZ | 140-260 | 270-380 | ≥30 | ||

| DX54D+AZ | 120-220 | 260-350 | ≥36 | ||

| For structureNational sign | S220GD+Z | ≥220 | ≥300 | ≥20 | |

| S250GD+Z | ≥250 | ≥330 | ≥19 | ||

| S280GD+Z | ≥280 | ≥360 | ≥18 | ||

| S320GD+Z | ≥320 | ≥390 | ≥17 | ||

| S350GD+Z | ≥350 | ≥420 | ≥16 | ||

| S550GD+Z | ≥550 | ≥560 | |||

Surface Finish:

![]()

| Name | Code | Instructions |

| Ordinary surface | FA | Ordinary surface |

| Higher finish surface | FB | Small corrosion points, dark spots, band marks, zinc particles, passivation defects are allowed |

| High finish surface | FC | No corrosion spots are allowed, but minor indentation, scratch, zinc flow ripple, minor passivation defects are allowed in a small area, and the FA surface is maintained on the other side at least |

| Name | other name | Instructions |

| No Spangle | 0 Spangle; Spangle Free | zinc-coated steel sheet with a uniform finish in which the surface irregularities created by spangle formation are not visible to the naked eye. The finish is produced by a combination of coating bath chemistry, or cooling. |

| Small Spangle | Minimized spangle | zinc-coated steel sheet in which the grain pattern is visible to the unaided eye, and is typically smaller and less distinct than the pattern visible on regular spangle. The zinc crystal growth is arrested by special production techniques, or is inhibited by a combination of coating bath chemistry plus cooling. |

| Regular Spangle | Simple Spangle | zinc-coated steel sheet with a visible multifaceted zinc crystal structure. The cooling rate is uncontrolled, which produces a variable grain size. |

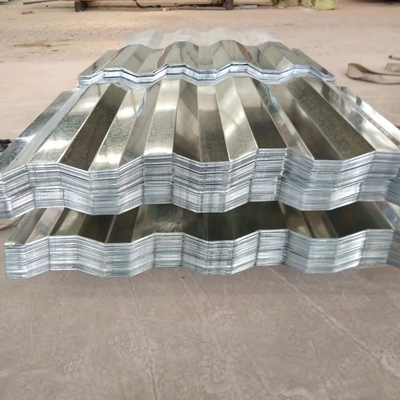

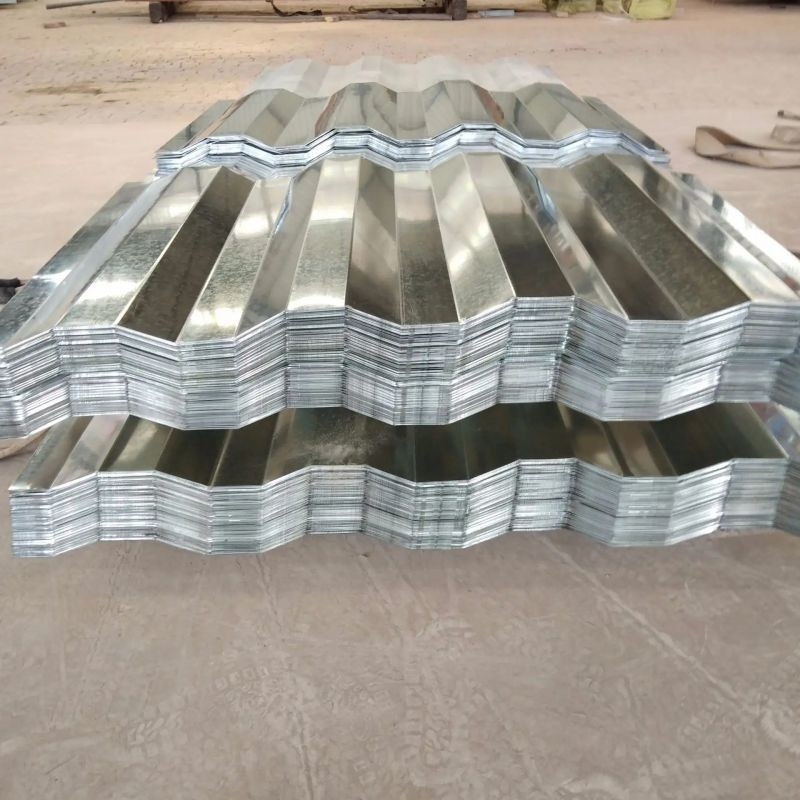

Product Display:

![]()

![]()

Packing:

Dx52D SECC Galvanized Corrugated Roof Sheet 0.5mm CGI SGCC SPEC Packing 2 types:

l Standard packing

![]()

l Fine packing

![]()

WHY CHOOSE US:

Q1: What is your terms of payment?

A: 30% T/T in advance, the balance 70% before delivery. We will show you the photos of products and package before you pay the balance.

Q2: what is the terms of delivery?

A: FOB, CIF, CFR,

Q3: What is the terms of packing?

A: generally, we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers' requirement.

Q4: What is your delivery time?

A: For stocks, we could transport the goods to loading port within 7 days after we received your deposit.

For production period, it usually takes about 15 days-30 days after receiving the deposit.

Q5: Could you produce according to the samples?

A : Yes, we could customer-made by your samples or technique drawings, we could build the mold and fixtures.

Q6: Could you provide the samples?

A: yes, we could provide the free samples on conditons it is available in stocks, however, the the transportation fee is borne by buyer.