Cold Rolled ERW Nickel Alloy Coil 0.3mm 0.5mm Thickness

Product Details:

| Place of Origin: | China;America |

| Brand Name: | HAYNES; DONCA;BAOSTEEL |

| Certification: | MTC; SGS |

| Model Number: | 718 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 400 KG |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Pipes be covered with waterproof protective packing materials; |

| Delivery Time: | 18-30 working days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 40 tons per month |

|

Detail Information |

|||

| Name: | High Quality Nickel Based Alloy 0.3mm 0.5mm Thickness Cold Rolled Nickel Alloy Coil | Application: | Chromatography/Hydraulic/High Pressure, For Fluid And Gas Transport |

|---|---|---|---|

| Outer Diameter: | 167 Mm | Inner Diameter: | 158 Mm |

| Length: | 184 Mm | Finish: | As Customer's Requirments |

| Processing Service: | Bending, Cutting, Decoiling, Moulding, Punching, Welding | Invoicing: | By Actual Weight |

| Welding Line Type: | ERW | Model Numbe: | 718 |

| Highlight: | Cold Rolled Nickel Alloy Coil,0.3mm Nickel Alloy Coil,ERW Nickel Alloy Coil 0.5mm |

||

Product Description

Inconel 718 is a nickel-chromium-molybdenum alloy designed to resist a wide range of severely corrosive environments, pitting and crevice corrosion. This nickel steel alloy also displays exceptionally high yield, tensile, and creep-rupture properties at high temperatures. This nickel alloy is used from cryogenic temperatures up to long term service at 1200° F. One of the distinguishing features of Inconel 718’s composition is the addition of niobium to permit age hardening which allows annealing and welding without spontaneous hardening during heating and cooling. The addition of niobium acts with the molybdenum to stiffen the alloy’s matrix and provide high strength without a strengthening heat treatment. Other popular nickel-chromium alloys are age hardened through the addition of aluminum and titanium. This nickel steel alloy is readily fabricated and may be welded in either the annealed or precipitation (age) hardened condition. This superalloy is used in a variety of industries such as aerospace, chemical processing, marine engineering, pollution-control equipment, and nuclear reactors.

Product introduction:

| Commodity | Nickel Alloy Steel Tubes C-276 NS3304 Diameter 167mm Welded And Seamless Pipe |

| Grade | C276 |

| Brand | HAYNES; BAOSTEEL |

| Certification | SGS,BV,IQI,TUV,ISO,etc |

| Wall Thickness | 1.5-30mm |

| Outside diameter | 6-630mm |

| Length | 1000-6000mm |

| Surface | pickled, polish, brush, mirror |

| Technique | seamless, welded |

| Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

| Delivery time | About 15 -30 days or based on the sales contract |

| MOQ | 1 Ton |

| Advantages |

Stainless steel pipe applies to petroleum, chemical industry, electric power, boiler ,high temperature resistant low temperature resistant ,corrosion resistant seamless steel pipe used. Stainless steel pipe and other material can be made according to the customers’ requirements.

|

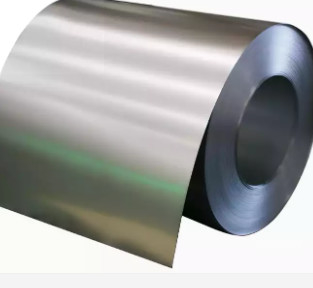

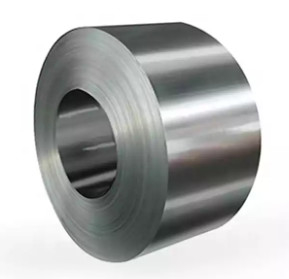

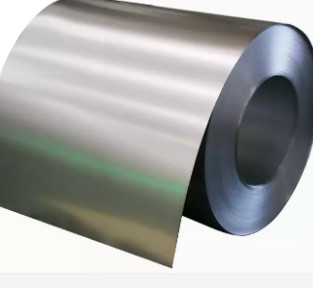

Product Display :

![]()

![]()

Chemical Composition:

| Chemical Requirements | |||||||

| Ni | Cr | Mn | Mo | C | Si | Fe | |

| Max % | Bal. | 16.5 | 1 | 17 | 0.01 | 0.08 | 7 |

| Min % | 14.5 | 15 | 4 | ||||

Physical Property:

| Mechanical Property Requirments | |||||

| Ultimate Tensile | Yield Strength(0.2% OS) | Elong.in 2 in.(50.8mm)or 4D min, % | R/A | Hardness | |

| Min | 100 KSI | 41 KSI | 40 KSI | ||

| Max | |||||

| Min Metric | 600 MPa | 283 MPa | |||

| Max | |||||

Hastelloy C-276 alloy is an improved wrought version of Hastelloy alloy C. HASTELLOY C-4 alloy is a nickel-chromium-molybdenum Hastelloy alloy with good high-temperature stability. The Hastelloy C-4 is an Hastelloy grade, that resists the formation of grain-boundary precipitates in weld heat-affected zones.

SCH Table:

![]()

Surface Finish:

![]()

Packaging:

![]()

Hollow Hastelloy C276 C22 C4 C2000 B2 B3 Pipe Polish Brush Mirror Finish Packaging Details:

1: Pipes be covered with waterproof protective packing materials;

2: Then be bundled with strips together;

3: Well loaded and be transported to the loading port.

The inner size container as below:

1:20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM ;

2:40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM ;

3:40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM.

WHY CHOOSE US:

Q1: What is your terms of payment?

A: 30% T/T in advance, the balance 70% before delivery. We will show you the photos of products and package before you pay the balance.

Q2: what is the terms of delivery?

A: FOB, CIF, CFR,

Q3: What is the terms of packing?

A: generally, we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers' requirement.

Q4: What is your delivery time?

A: For stocks, we could transport the goods to loading port within 7 days after we received your deposit.

For production period, it usually takes about 15 days-30 days after receiving the deposit.

Q5: Could you produce according to the samples?

A : Yes, we could customer-made by your samples or technique drawings, we could build the mold and fixtures.

Q6: Could you provide the samples?

A: yes, we could provide the free samples on conditons it is available in stocks, however, the the transportation fee is borne by buyer.