BS NA14 Inconel Nickel Alloy Steel Welded Pipe 600 UNS No6600 Round Tube

Product Details:

| Place of Origin: | China;America |

| Brand Name: | HAYNES; VDM;NIPPON |

| Certification: | MTC; SGS |

| Model Number: | Inconel 600 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 0.05 Ton |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Pipes be covered with waterproof protective packing materials; |

| Delivery Time: | 15-30 working days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 30 tons per month |

|

Detail Information |

|||

| Name: | BS NA14 Seamless Pipes | Shape: | Round |

|---|---|---|---|

| Type: | Nickel Pipe | Surface: | Pickled |

| Length: | 6 M | Elongation (≥ %): | 30% |

| Kind: | Inconel Alloy | Grade: | Inconel 600 |

| Similar Material: | UNS N06600; DIN 2.4816 | MOQ: | 50 Kg |

| Highlight: | Inconel Nickel Alloy Steel Welded Pipe,BS NA14 Nickel Alloy Steel Pipe,Nickel Alloy Steel No6600 Round Pipe |

||

Product Description

DIN W.Nr.2.4816 BS NA14 Inconel 600 UNS No6600 Alloy Round Tube SLMS Welded Pipe

INCONEL (nickel-chromium-iron) alloy 600 (UNS N06600/W.Nr. 2.4816) is a standard engineering material for applications which require resistance to corrosion and heat. The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability.

Grades 200 and 201 nickel are normally preferred for handling concentrated, high temperature caustic. However, when sulfur compounds are present as well, or for ammonium hydroxide service, 600 alloy is suggested. 600 alloy is subject to stress corrosion cracking in hot, concentrated caustic alkalies. To avoid stress corrosion cracking, the 600 alloy fabrication should be fully stress relieved prior to use. A minimum treatment of 1650°F for 1 hour is suggested, but 1800-1850°F for 1 hour preferred.

Product introduction:

| Commodity | DIN W.Nr.2.4816 BS NA14 Inconel 600 UNS No6600 Alloy Round Tube SLMS Welded Pipe |

| Grade | Inconel |

| Brand | HAYNES; Ronsco |

| Certification | SGS,BV,IQI,TUV,ISO,etc |

| Wall Thickness | 1.5-30mm |

| Outside diameter | 6-630mm |

| Length | 1000-6000mm |

| Surface | pickled |

| Technique | seamless |

| Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

| Delivery time | About 15 -30 days or based on the sales contract |

| MOQ | 1 Ton |

| Advantages |

Stainless steel pipe applies to petroleum, chemical industry, electric power, boiler ,high temperature resistant low temperature resistant ,corrosion resistant seamless steel pipe used. Stainless steel pipe and other material can be made according to the customers’ requirements.

|

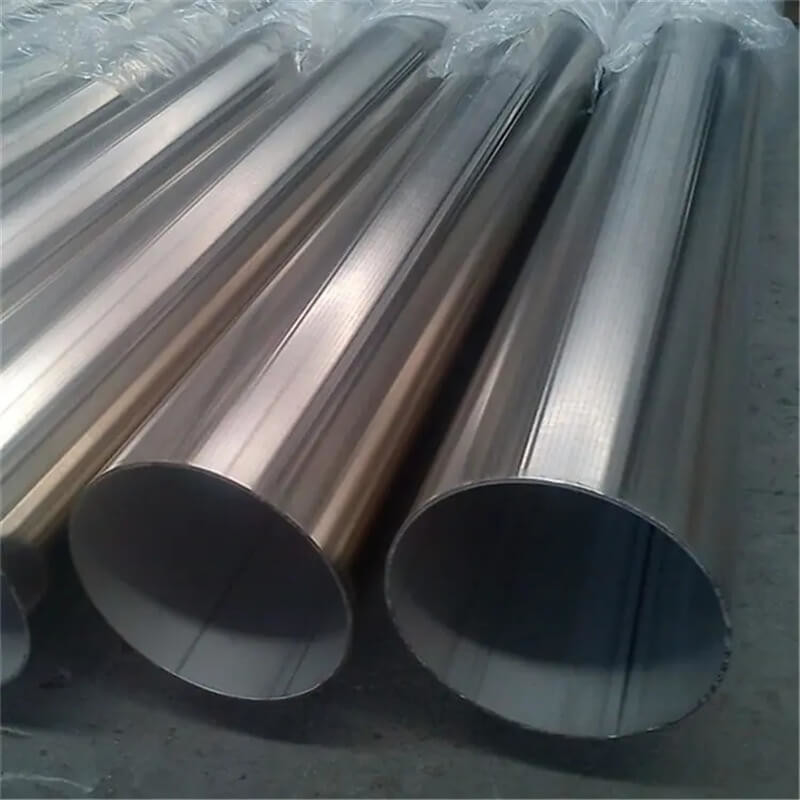

Product Display :

![]()

![]()

Features

- Virtually immune to chloride ion stress corrosion cracking

- Good caustic corrosion resistance

- Resistant to dry Cl2 to about 1000°F

- Oxidation resistance to 2000°F

- Carburization resistance

Physical Property:

| Mechanical Property Requirments | |||||

| Ultimate Tensile | Yield Strength(0.2% OS) | Elong.in 2 in.(50.8mm)or 4D min, % | R/A | Hardness | |

| Min | 100 KSI | 41 KSI | 40 KSI | ||

| Max | |||||

| Min Metric | 600 MPa | 283 MPa | |||

| Max | |||||

Applications

-

Heat treating muffles and retorts

-

Vacuum furnace fixtures

-

Chlorination equipment to 1000°F

-

Titanium dioxide plants

Surface Finish:

![]()

Packaging:

![]()

DIN W.Nr.2.4816 BS NA14 Inconel 600 UNS No6600 Alloy Round Tube SLMS Welded Pipe

Packaging Details:

1: Pipes be covered with waterproof protective packing materials;

2: Then be bundled with strips together;

3: Well loaded and be transported to the loading port.

The inner size container as below:

1:20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM ;

2:40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM ;

3:40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM.

WHY CHOOSE US:

Q1: What is your terms of payment?

A: 30% T/T in advance, the balance 70% before delivery. We will show you the photos of products and package before you pay the balance.

Q2: what is the terms of delivery?

A: FOB, CIF, CFR,

Q3: What is the terms of packing?

A: generally, we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers' requirement.

Q4: What is your delivery time?

A: For stocks, we could transport the goods to loading port within 7 days after we received your deposit.

For production period, it usually takes about 15 days-30 days after receiving the deposit.

Q5: Could you produce according to the samples?

A : Yes, we could customer-made by your samples or technique drawings, we could build the mold and fixtures.

Q6: Could you provide the samples?

A: yes, we could provide the free samples on conditons it is available in stocks, however, the the transportation fee is borne by buyer.