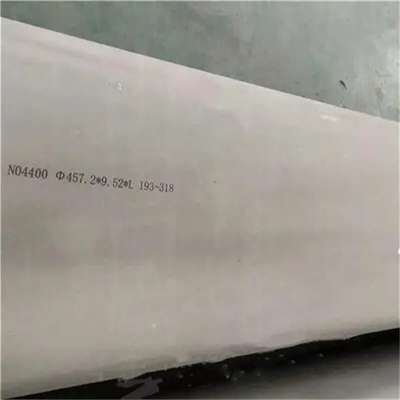

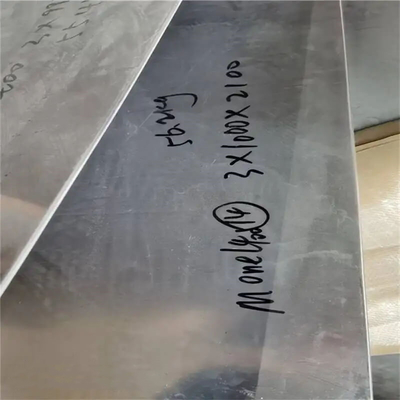

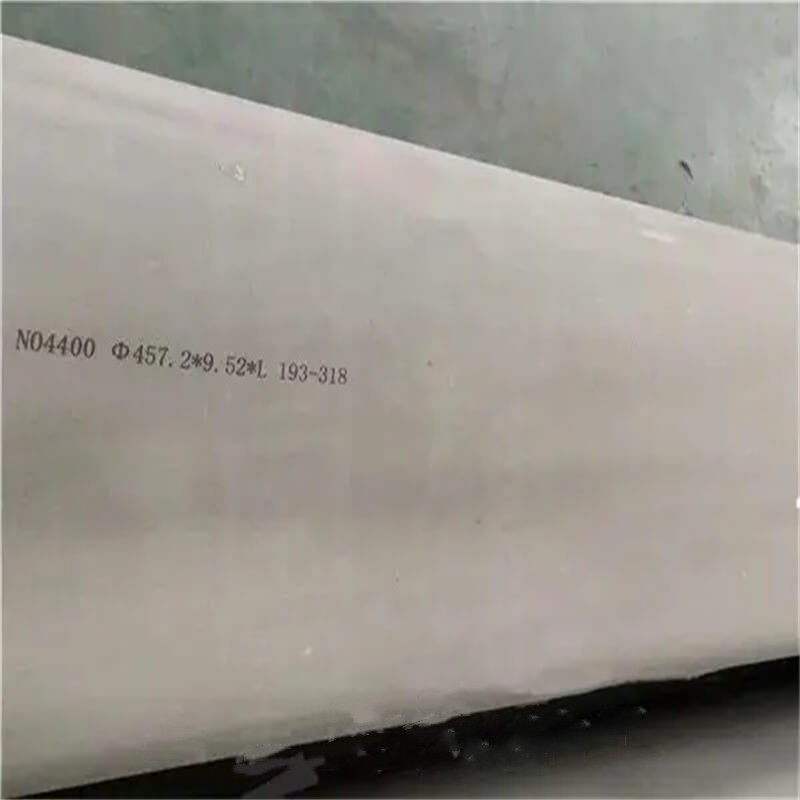

Copper Nickel Alloy Monel Steel Plate N04400 400 Sheet Corrosion Resistance

Product Details:

| Place of Origin: | China |

| Brand Name: | Monel; |

| Certification: | MTC; SGS |

| Model Number: | Monel 400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 0.1 Ton |

|---|---|

| Price: | Negotiable |

| Packaging Details: | waterproof paper and steel strip reinforcement,one package about 2 tons,Load in 20' or 40' GP |

| Delivery Time: | 3-15 working days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 tons per month |

|

Detail Information |

|||

| Name: | Nickel Monel 400 Din 1743 Plate | Type: | Nickel Plate, Bare |

|---|---|---|---|

| Application: | Corrosion Resistance High Temperature | Grade: | Nickel Copper Alloy |

| Service: | Sample | Ni (Min): | 63 |

| UNS: | NO4400 | Surface: | Bright, Oxidized Or Pickling |

| Heat Treatment: | Solid Solution And Aging Treatment | Density: | 8.8g/cm3 |

| Highlight: | Copper Nickel Alloy Monel Plate,N04400 Nickel Alloy Plate,Corrosion Resistance Monel Steel Plate |

||

Product Description

Monel 400 UNS NO4400 Cold Rolled Alloy Plate Hot Rolled Nickel Sheet

In the most basic terms INCONEL® is a nickel-chromium alloy whereas MONEL® is a nickel-copper alloy. Both metals are commonly used in applications with extreme heat, high temperature corrosion, and generally severe conditions

Product introduction:

| Commodity |

Monel 400 UNS NO4400 Cold Rolled Alloy Plate Hot Rolled Nickel Sheet |

| Grade | Monel 400 |

| Brand | |

| Certification | SGS,BV,IQI,TUV,ISO,etc |

| Thickness | 0.5mm 2mm |

| Width |

1000mm,1219mm,1500mm as per customers’ requirements |

| Length | 2000,3000,6000mm or as per customers’ requirements |

| Surface | 2B BA Mirror |

| Standard |

JIS,AISI,ASTM,GB,DIN |

| Delivery time | About 15 -30 days or based on the sales contract |

| MOQ | 1 Ton |

| Advantages |

combining excellent high temperature properties with good ductility and weldability |

Gauge and Thickness Inch:

| Gauge | Mild Steel | Aluminum | Galvanized Steel | Stainless Steel |

| 3 | 0.2391 | 0.2294 | 0.2500 | |

| 4 | 0.2242 | 0.2043 | 0.2344 | |

| 5 | 0.2092 | 0.1819 | 0.2187 | |

| 6 | 0.1943 | 0.1620 | 0.2031 | |

| 7 | 0.1793 | 0.1443 | 0.1875 | |

| 8 | 0.1644 | 0.1285 | 0.1680 | 0.1650 |

| 9 | 0.1495 | 0.1144 | 0.1532 | 0.1562 |

| 10 | 0.1345 | 0.1019 | 0.1382 | 0.1406 |

| 11 | 0.1196 | 0.0907 | 0.1233 | 0.1250 |

| 12 | 0.1046 | 0.0808 | 0.1084 | 0.1094 |

| 13 | 0.0897 | 0.0720 | 0.0934 | 0.0937 |

| 14 | 0.0747 | 0.0641 | 0.0785 | 0.0781 |

| 15 | 0.0673 | 0.0571 | 0.0710 | 0.0703 |

| 16 | 0.0598 | 0.0508 | 0.0635 | 0.0625 |

| 17 | 0.0538 | 0.0453 | 0.0575 | 0.0562 |

| 18 | 0.0478 | 0.0403 | 0.0516 | 0.0500 |

| 19 | 0.0418 | 0.0359 | 0.0456 | 0.0437 |

| 20 | 0.0359 | 0.0320 | 0.0396 | 0.0375 |

| 21 | 0.0329 | 0.0285 | 0.0366 | 0.0344 |

| 22 | 0.0299 | 0.0253 | 0.0336 | 0.0312 |

| 23 | 0.0269 | 0.0226 | 0.0306 | 0.0281 |

| 24 | 0.0239 | 0.0201 | 0.0276 | 0.0250 |

| 25 | 0.0209 | 0.0179 | 0.0247 | 0.0219 |

| 26 | 0.0179 | 0.0159 | 0.0217 | 0.0187 |

| 27 | 0.0164 | 0.0142 | 0.0202 | 0.0172 |

| 28 | 0.0149 | 0.0126 | 0.0187 | 0.0156 |

| 29 | 0.0135 | 0.0113 | 0.0172 | 0.0141 |

| 30 | 0.0120 | 0.0100 | 0.0157 | 0.0125 |

| 31 | 0.0105 | 0.0089 | 0.0142 | 0.0109 |

| 32 | 0.0097 | 0.0080 | 0.0134 | 0.0102 |

| 33 | 0.0090 | 0.0071 | 0.0094 | |

| 34 | 0.0082 | 0.0063 | 0.0086 | |

| 35 | 0.0075 | 0.0056 | 0.0078 | |

| 36 | 0.0067 | 0.0070 |

Surface Finish:

![]()

#1 - Monel 400 is hot rolled annealed and descaled. It is available in strip, foil and ribbon. It is used for applications where a smooth decorative finish is not required.

#2D - Dull finish Alloy 400 produced by cold rolling, annealing and descaling. Used for deep drawn parts and those parts that need to retain lubricants in the forming process.

#2B - Smooth finish produced by cold rolling, annealing and descaling. A light cold rolling pass is added after anneal with polished rolls giving it a brighter finish than 2D.

#BA- Bright annealed cold rolled and bright annealed

#CBA- Course bright annealed cold rolled matte finish and bright anneal

#2 - Cold Rolled Monel 400 Finish

#2BA- Smooth finish produced by cold rolling and bright annealing. A light pass using highly polished rolls produces a glossy finish. A 2BA finish may be used for lightly formed applications where a glossy finish is desired in the formed part.

Polished - Various grit finish for specific polish finished requirements.

Brand Cross Reference Table:

| GB NEW BRAND | JIS | ASTM | UNS | KS | BS EN | AS |

| 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 201-2 |

| 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - |

| 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 301 |

| 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 304 |

| 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 304L |

| 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | 304N1 |

| 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | 304N2 |

| 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | - | 304LN |

| 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | 305 |

| 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | 309S |

| 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | 310S |

| 06Cr17Ni12Mo2 | SUS316 | 3016 | S31600 | STS316 | 1.4401 | 316 |

| 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | - | 1.4571 | 316Ti |

| 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 316L |

| 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | - | 316N |

| 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | 316LN |

| 06Cr18Ni12Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | 316J1 |

| 022Cr18Ni14Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - |

| 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | - | 317 |

| 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | 317L |

| 06Cr18Ni11Tji | SUS321 | 321 | S32100 | STS321 | 1.4541 | 321 |

| 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.455 | 347 |

| 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 410 |

| 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 420 |

| 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 430 |

Product Display:

![]()

![]()

Packing:

Monel 400 UNS NO4400 Cold Rolled Alloy Plate Hot Rolled Nickel Sheet Packing 2 types:

l Standard packing

![]()

l Fine packing

![]()

Gas-arc welding, metal-arc welding, gas-metal-arc welding and submerged-arc welding are recommended for Monel 400. When hot-working Monel 400, temperatures should range from 648-1,176 degrees Celsius (1,200-2,150 degrees Fahrenheit). It can be annealed at 926 degrees Celsius (1,700 degrees Fahrenheit).

Factory and Machine Equipment:

We had our own factory to do slitting re-rolling and finish treatment machine,PVC and interleaving paper we will using with our machine for you,could protect stainless steel surface from damage or any scratches,

1. CNC Flame Cutting Machine

2. CNC Plasma Cutting Machine

3. CNC Laser Cutting Machine

4. Bending Machine

5. Shearing Machine

6. Punch Machine

7. Driving Machine

WHY CHOOSE US:

Q1: What is your terms of payment?

A: 30% T/T in advance, the balance 70% before delivery. We will show you the photos of products and package before you pay the balance.

Q2: what is the terms of delivery?

A: FOB, CIF, CFR,

Q3: What is the terms of packing?

A: generally, we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers' requirement.

Q4: What is your delivery time?

A: For stocks, we could transport the goods to loading port within 7 days after we received your deposit.

For production period, it usually takes about 15 days-30 days after receiving the deposit.

Q5: Could you produce according to the samples?

A : Yes, we could customer-made by your samples or technique drawings, we could build the mold and fixtures.

Q6: Could you provide the samples?

A: yes, we could provide the free samples on conditons it is available in stocks, however, the the transportation fee is borne by buyer.