NO7718 Nickel Alloy Steel Cold Rolled Sheet GH169 CRC 2.4668 1000x2000x2mm

Product Details:

| Place of Origin: | China |

| Brand Name: | VDM;HAYNES |

| Certification: | MTC; SGS |

| Model Number: | Inconel 718 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 0.1 Ton |

|---|---|

| Price: | Negotiable |

| Packaging Details: | waterproof paper and steel strip reinforcement,one package about 2 tons,Load in 20' or 40' GP |

| Delivery Time: | 3-15 working days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 tons per month |

|

Detail Information |

|||

| Name: | Inconel 718 Sheet Very High Hardness | Type: | Nickel Plate, Bare |

|---|---|---|---|

| Application: | Corrosion Resistance High Temperature | Grade: | Inconel |

| Elongation: | ≥ 40% | Melting Point: | 1060-1340°c |

| UNS: | NO7718 | Standard: | ASTM B670; ASTM B906; ASM 5596; AMS 5597 |

| Heat Treatment: | Solid Solution And Aging Treatment | Density: | 8.2g/cm3 |

| Highlight: | Cold Rolled Nickel Alloy Steel Sheet,NO7718 Nickel Alloy Steel Sheet,1000x 2000x 2 mm Alloy Steel Sheet |

||

Product Description

UNS NO7718 Cold Rolled Plate Alloy Nickel 2mm Thickness Sheet

Inconel 718 is a nickel-chromium-molybdenum alloy designed to resist a wide range of severely corrosive environments, pitting and crevice corrosion. This nickel steel alloy also displays exceptionally high yield, tensile, and creep-rupture properties at high temperatures.

Product introduction:

|

Commodity |

UNS NO7718 Cold Rolled Plate Alloy Nickel 2mm Thickness Sheet

|

| Grade |

Inconel 718 |

| Brand | HAYNES;Nippon |

| Certification | SGS,BV,IQI,TUV,ISO,etc |

| Thickness | 2mm |

| Width |

1000 mm |

| Length | 2000 mm |

| Surface | 2B BA Mirror |

| Standard |

JIS,AISI,ASTM,GB,DIN |

| Delivery time | About 15 -30 days or based on the sales contract |

| MOQ | 1 Ton |

| Advantages |

combining excellent high temperature properties with good ductility and weldability |

Chemical:

| Element | Min | Max | ||

| Al(Aluminium) | 0.20% | 0.80% | ||

| B(Boron ) | 0.006% | |||

| C(Carbon) | 0.08% | |||

| Co(Cobalt) | 1% | |||

| Cr(Chromium) | 17% | 21% | ||

| Cu(Copper) | 0.30% | |||

| Mn(Manganese) | 0.35% | |||

| Mo(Molybdenum) | 2.80% | 3.30% | ||

| Nb(Niobium) | 4.75% | 5.50% | ||

| Ni(Nickel) | 50% | 55% | ||

| P(Phosphorus) | 0.015% | |||

| S(Sulphur) | 0.015% | |||

| Si(Silicon) | 0.35% | |||

| Ti(Titanium) | 0.65% | 1.15% | ||

| Iron | Balance | |||

Surface Finish:

![]()

Inconel 718 may be produced through the following processes:

- Annealing: The metal is exposed to heat and then gradually brought down to lower temperature. This gives the material its strength and resistance to stress.

- Precipitation hardening: Also called age hardening or precipitation heat treatment, this method boosts the alloy’s strength by introducing impurities before heating.

In annealing – or also called solid solution strengthening – metal components are dissolved completely so that they will precipitate properly to give Inconel 718 the strength that it is designed to have.

In precipitation strengthening, nickel and niobium combine to form gamma double prime (or Ni3Nb). Extreme heat at above 800°C causes the nickel phases to precipitate.

From this, Inconel 718 may be processed into custom shapes and orientations when machined above 540°C.

Brand Cross Reference Table:

| GB NEW BRAND | JIS | ASTM | UNS | KS | BS EN | AS |

| 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 201-2 |

| 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - |

| 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 301 |

| 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 304 |

| 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 304L |

| 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | 304N1 |

| 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | 304N2 |

| 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | - | 304LN |

| 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | 305 |

| 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | 309S |

| 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | 310S |

| 06Cr17Ni12Mo2 | SUS316 | 3016 | S31600 | STS316 | 1.4401 | 316 |

| 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | - | 1.4571 | 316Ti |

| 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 316L |

| 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | - | 316N |

| 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | 316LN |

| 06Cr18Ni12Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | 316J1 |

| 022Cr18Ni14Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - |

| 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | - | 317 |

| 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | 317L |

| 06Cr18Ni11Tji | SUS321 | 321 | S32100 | STS321 | 1.4541 | 321 |

| 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.455 | 347 |

| 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 410 |

| 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 420 |

| 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 430 |

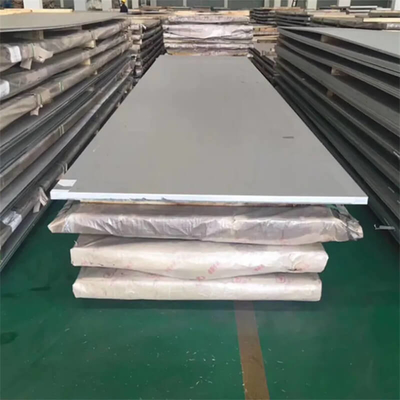

Product Display:

![]()

![]()

Packing:

UNS NO7718 Cold Rolled Plate Alloy Nickel 2mm Thickness Sheet Packing 2 types:

l Standard packing

![]()

l Fine packing

![]()

INCONEL alloy 718 is ideal for use in these circumstances. For example, it has been used in jet engine and high-speed airframe parts, including wheels, fasteners, instrumentation parts, bolts, spacers and buckets.

Factory and Machine Equipment:

We had our own factory to do slitting re-rolling and finish treatment machine,PVC and interleaving paper we will using with our machine for you,could protect stainless steel surface from damage or any scratches,

1. CNC Flame Cutting Machine

2. CNC Plasma Cutting Machine

3. CNC Laser Cutting Machine

4. Bending Machine

5. Shearing Machine

6. Punch Machine

7. Driving Machine

WHY CHOOSE US:

Q1: What is your terms of payment?

A: 30% T/T in advance, the balance 70% before delivery. We will show you the photos of products and package before you pay the balance.

Q2: what is the terms of delivery?

A: FOB, CIF, CFR,

Q3: What is the terms of packing?

A: generally, we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers' requirement.

Q4: What is your delivery time?

A: For stocks, we could transport the goods to loading port within 7 days after we received your deposit.

For production period, it usually takes about 15 days-30 days after receiving the deposit.

Q5: Could you produce according to the samples?

A : Yes, we could customer-made by your samples or technique drawings, we could build the mold and fixtures.

Q6: Could you provide the samples?

A: yes, we could provide the free samples on conditons it is available in stocks, however, the the transportation fee is borne by buyer.