TP201 Cold Rolled Stainless Steel Sheet 1mm 1.2 1.5mm Mirror Finish 8K

Product Details:

| Place of Origin: | China |

| Brand Name: | TISCO,BAOSTEEL,POSCO,JISCO,LISCO |

| Certification: | MTC; SGS |

| Model Number: | 201 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Ton |

|---|---|

| Price: | Negotiable |

| Packaging Details: | waterproof paper and steel strip reinforcement,one package about 2 tons,Load in 20' or 40' GP |

| Delivery Time: | 7-15 working days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 300 tons per month |

|

Detail Information |

|||

| Name: | Cold Rolled 201 Stainless Steel Sheet | Surface: | 8K |

|---|---|---|---|

| Technique: | Cold Rolled | Price Term: | FOB, CFR, CIF |

| Packing: | Standard Sea-worthy Packing | Tolerance: | -5% |

| Thickness: | 1 Mm,1.2mm, 1.5mm | Grade: | 201 |

| Width: | 1 000nm,1219m | Length: | 2000 Nm,3000mm,6000mm |

| Highlight: | Mirror Stainless Steel Sheet Cold Rolled,TP201 Stainless Steel Sheet,8K 1.5mm Stainless Steel Sheet |

||

Product Description

TP201 Cold Rolled Stainless Steel Sheet Thickness 1mm,1.2,1.5mm Mirror Finish 8K Finish

Stainless steel mirror processing, simply speaking is to polish the surface of stainless steel, through rough grinding,

two rough grinding, half fine grinding, fine grinding, two fine grinding, half light, light seven process steps, with different

sand belt, wheel and cloth wheel repeatedly polishing, finally obtain ordinary polishing, ordinary 6K, fine grinding 8K

Product introduction:

| Commodity | TP201 Cold Rolled Stainless Steel Sheet Thickness 1mm,1.2,1.5mm Mirror Finish 8K Finish |

| Grade | 201 |

| Brand | LISCO ,JIANGSU DELONG, HONGWANG |

| Certification | SGS,BV,IQI,TUV,ISO,etc |

| Thickness |

1mm |

| Width | 1000 1219 1250mm or as customer's requirments |

| Length | 2000 3000 6000 mm or as customer's requirments |

| Surface | mirror |

| Standard | JIS,AISI,ASTM,GB,DIN |

| Delivery time | About 15 -30 days or based on the sales contract |

| MOQ | 1 Ton |

| Advantages | Widely used in decoration use |

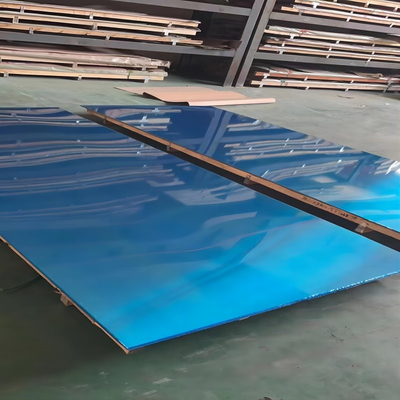

Product Display :

![]()

![]()

Difference with 304 :

201 is high manganese content, the surface is very bright with dark bright, high manganese content is easy to

rust. 304 contains more chromium, the surface is matte, no rust. Put the two together and you have a comparison.

The most important thing is that the corrosion resistance is different. The corrosion resistance of 201 is very poor,

so the price will be much cheaper. Because of the low nickel content of 201, the price is lower than 304, so the

corrosion resistance is not as good as 304.

Chemical Composition:

| Grade | C | Si | Mn | P | S | Ni | Cr | |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | ≤0.06 | ≤0.03 | 0.8-1.0 | 16.00~18.00 |

Physical Property:

| Grade | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) | HBW | HRB | HV | Density |

| 201 | ≥520 | ≥275 | ≥55 | ≤241 | ≤100 | ≤253 | 7.93g/cm |

Surface Finish:

![]()

| Surface Finish | Definition | Application |

| 2B | Finished by heat treatment, pickling after cold rolling. Followed by skin pass line to be more brighter and smooth surface | General application Medical instruments, Tableware |

| BA | Bright heat treament after cold rolling | Kitchen utensil, kitchenware, architectural |

| 8K | A mirror-like reflective surface by polishing with finer abrasives over 800mesh | Construction, mirrors, plate sets, decoration elevators |

| HL | Finished by continuous linear polishing | Architectural purpose, Escalators, kitchenware, vehicles |

| NO.1 | Finished by hot rolling, annealing and picking, characterized by white pickled surface | Chemical industry Equipment, industrail tanks |

| NO.4 | Polishing with NO.150 to NO.180 mesh abrasives specified in JISR6001 | Kitchen utensils, Building Construction, Medical equipment |

Packing:

2 types:

l Standard packing

![]()

l Fine packing (extra cost )

![]()

Factory and Machine Equipment:

We had our own factory to do slitting re-rolling and finish treatment machine,PVC and interleaving paper we will using with our machine for you,could protect stainless steel surface from damage or any scratches,

1. CNC Flame Cutting Machine

2. CNC Plasma Cutting Machine

3. CNC Laser Cutting Machine

4. Bending Machine

5. Shearing Machine

6. Punch Machine

7. Driving Machine